Three-dimensional or additive manufacturing has its own characteristics, and in this field, the most important parameters that determine the effectiveness of work are, undoubtedly, the speed and accuracy. One of the newest trends in this field is the implementation of STP tessellation into 3D printing technologies. Bambu Labs, a prominent engineer and designer of 3D printing technology, recently implemented STP tessellation. But before going any further, let’s define what Bambu Labs STP tessellation actually is and how it is beneficial for 3D printing.

What is STP Tessellation?

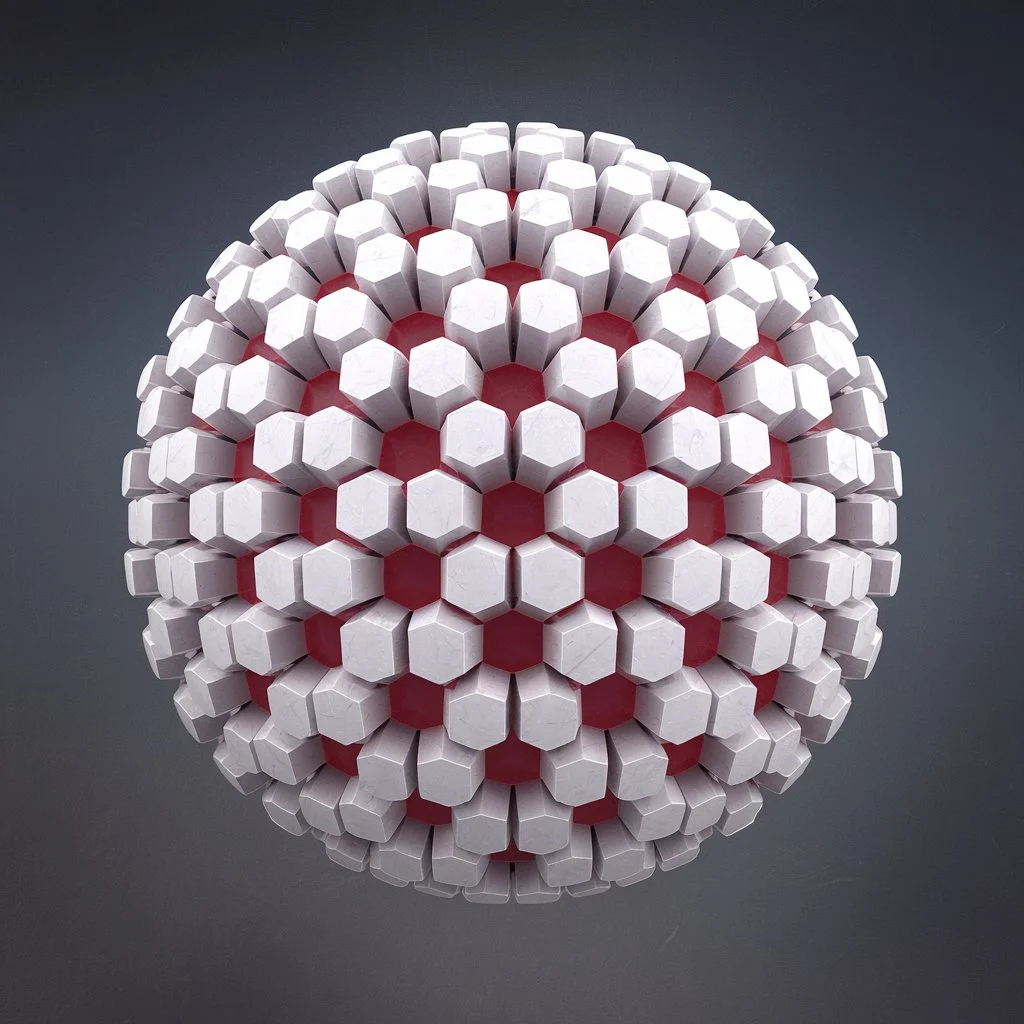

Tessellation is a branch of mathematics where different shapes fit together on a surface without leaving any space between them or overlapping. When considering 3D printing, a program best describes tessellation as the process of dividing a 3D model into several easily printable geometric elements, often triangles. The most common file format for representing 3D objects is the STP file format or Standard for the Exchange of Product Model Data.

Another key component of the Bambu Labs STP tessellation is the strategy of mapping the cumbersome 3D models into printable layers. Traditionally, once a designer prepares and completes a model, they slice it into layers, allowing the printer to build the object in small sections before joining them. Bambu Labs makes sure that it can build the model to precision and also guarantee the structural integrity of the finished printed object. The technology facilitates handling complex models and enhances print quality, and reduces the occurrences of errors.

Role of STP in 3D Printing

More often than not, models in 3D printing, are first designed in CAD software, and then exported in some format that a 3D printer can understand. Basically, STP format is much preferred in industrial applications because more information about the shape the object has to contain. Making an STP file printable in a desired format requires optimal tessellation. When tessellation is not optimized, small features in models can make 3D printers struggle. Resulting in imprecise shapes, poor finishes, or even failure to produce the part.

The Bambu Labs STP tessellation eliminates this flaw by providing improved partitioning of a model’s geometry. This is an advantage since the printer has the work well done without straining the design or omitting the fine details. Furthermore, Bambu Labs have developed specialized algorithms that optimize the tessellation process to reduce the time and materials required to 3D print the object.

How Bambu Labs STP Tessellation Works

It is an efficient method of parsing geometry of a model, using more printable objects, triangles, through the usage of progressive mathematical algorithms. One connects these triangles in a way that not only ensures the final result is as smooth and continuous as possible but also preserves its scale and position. Bambu Labs has found a sweet spot in its implementation, where it is specific without being overly prescriptive, demonstrating the strength of its bureaucracy.

To accomplish that, Bambu Labs STP tessellation does not convert the 3D printer into a data dump of the model, while keeping all the necessary data intact. This translates to faster time to print, reduced scrap rates and higher precision on the final finished product.

Advantages of Bambu Labs STP Tessellation

- Improved Accuracy: Another that lies in the increased accuracy in the printed models is one of the biggest strength of it. Through better management of the tessellation techniques used when subdividing the model, the final print resembles the design envisioned.

- Reduced Print Time: The large and intricate part models require a huge amount of time in printing. The STP tessellation of Bambu Labs simplifies the model geometry making it quicker to be processed by the printer, meaning that the time has been reduced.

- Minimized Material Waste: In most of the conventional 3D printing techniques, geometrically complex shapes lead to wastage of the printing material. This tessellation embedded in bambu Labs STP product design means that only a required amount of material is utilised to decrease wastage.

- Enhanced Surface Quality: One of the problems inherent in 3D printing is the surface roughness of the final object. Inefficiencies in tessellation can lead to layers or spaces visible upon its printing. Bambu Labs’ tessellation has been highly optimized which meant that the surface of the treated products was smoother and refined providing a better surface finish.

Applications

There are several advantages of Bambu Labs STP tessellation, especially for industries needs high accurate 3D printing like aerospace industries, automotive industries and manufacturing of medical equipment. Its capacity to flexibly work with complicated forms makes it a popular device for engineers and designers who require creating prototypes of complex parts.

For the hobbyists and low demand customers, it brings the pro quality in printing affordable from the industrial printers.

Conclusion

Bambu Labs STP tessellation shows a new level of 3D printing technology compared to previous inventions. This has exposed the organization to the most accurate, efficient and quality 3D printing standard the world has to offer through Bambu labs. From home project to industrial applications for creating components, Bambu Labs STP tessellation has the potential to help you gain results faster.